Experimental Workshop for melting, casting and processing of structural and functional materials

VNIINM, JSC owns an experimental workshop for melting, casting, and processing of structural and functional materials.

The workshop produces bars, plates, pipes made of refractory materials and alloys, hard-to-deform metals and alloys, structural steels, functional materials, non-ferrous metals and alloys.

The workshop employs modern equipment to produce:

- copper ingots and copper-based alloys (vacuum induction melting (VIM), vacuum arc melting (VAM);

- ingots of vanadium, niobium, titanium, zirconium, nickel and alloys based on these metals (vacuum arc melting (VAM));

- pipes made of stainless steel, copper, niobium, vanadium, tantalum, zirconium, hafnium, titanium and alloys of these metals, with the diameter of up to 8 mm;

- metal tapes made of stainless steel, copper, niobium, vanadium, tantalum, zirconium, hafnium, titanium and alloys of these metals, up to 0.2 mm thick and up to 160 mm wide.

1DRVG model vacuum arc furnace:

processed materials: Ti, Nb, V, Zr, Cu and alloys based on them.

Vanadium alloy ingots weighing 110 kg:

?= 180 мм;

?= 180 мм;

H = 500 мм;

Ingot weight up to 120 kg,

N=1000 kW;

Induction casting furnaces:

processed materials: Cu and copper alloys

processed materials: Cu and copper alloys

Bronze ingots made of BrO-14,5:

?= 160 мм;

H = 500 мм;

weight -200 кг,

N=120 kW;

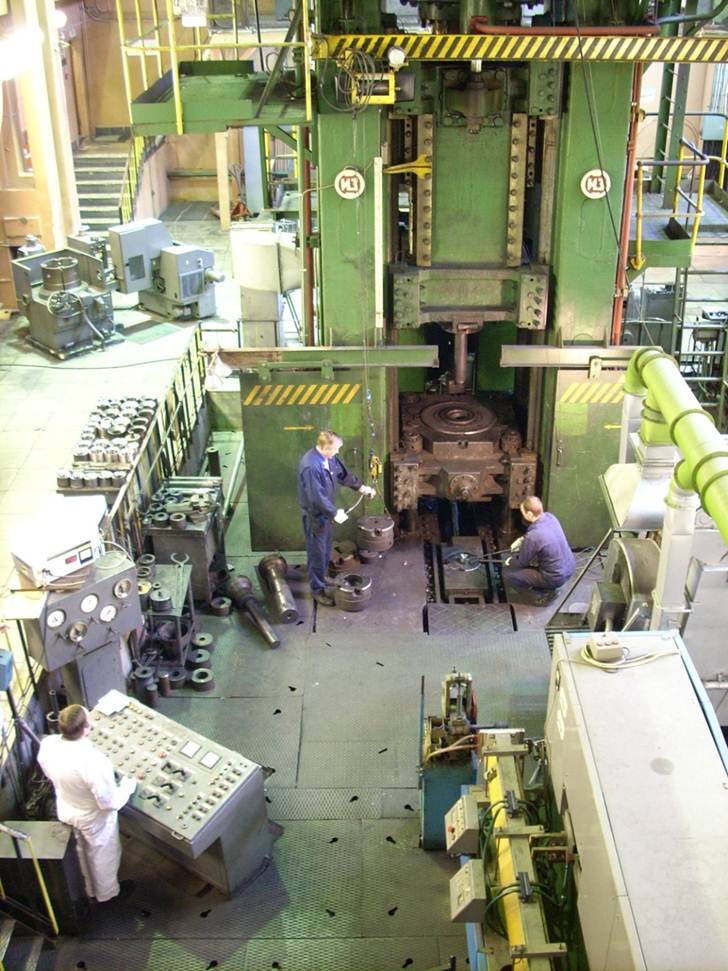

Hydraulic presses:

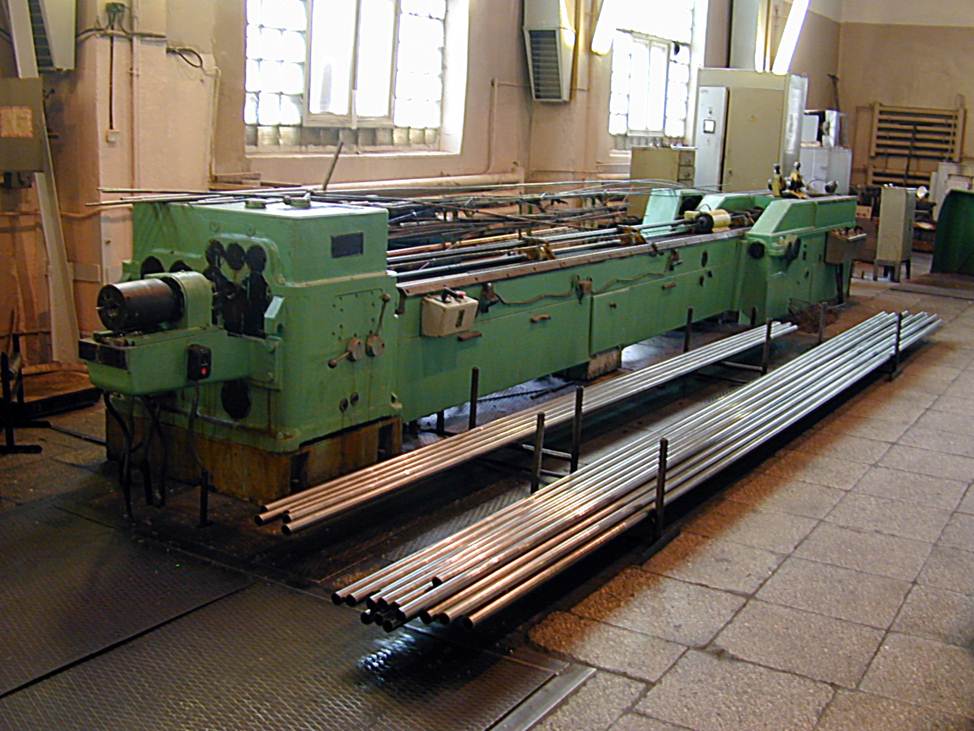

Cold rolling mills for pipes:

processed materials: stainless steels, Cu, Nb, V, Ta, Zr, Hf, Ti and their alloys.

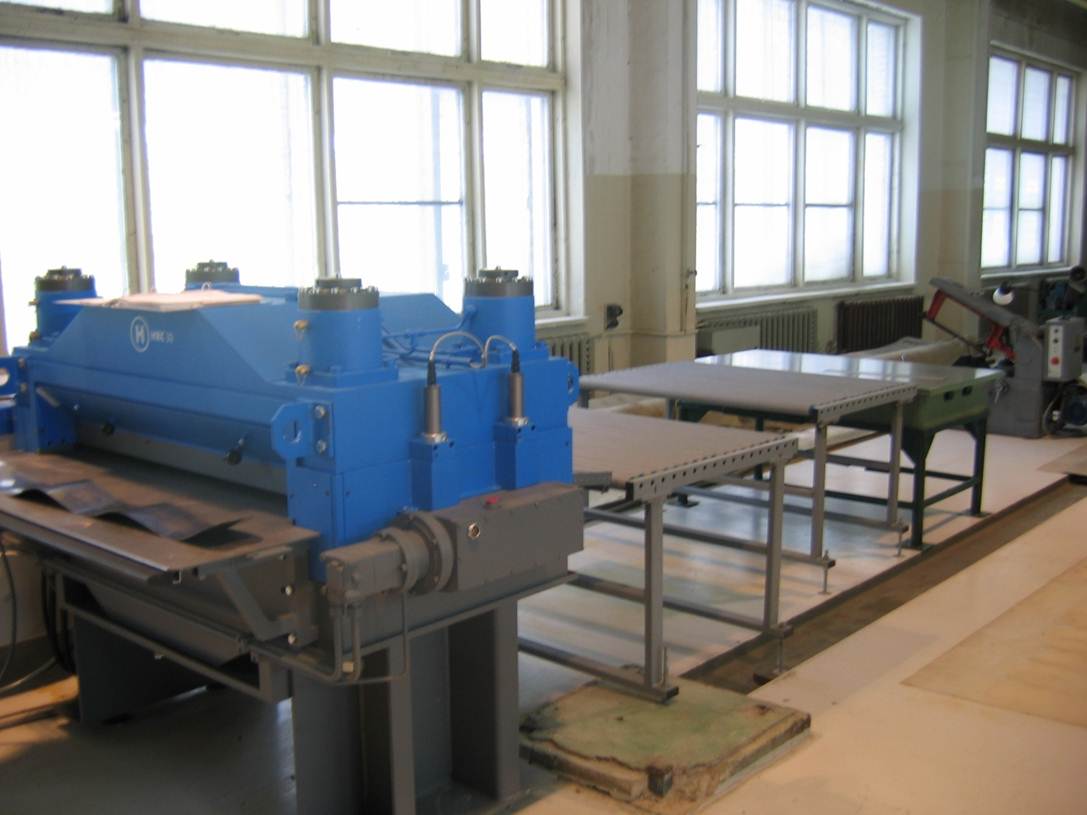

Sheet rolling mills:

Vacuum heating furnaces:

Radial forging machine:

Sheet straightening machine:

Machining: